Top Hanger Bolt Manufacturers in China: Discover Leading Suppliers for Your Projects

2026-01-06

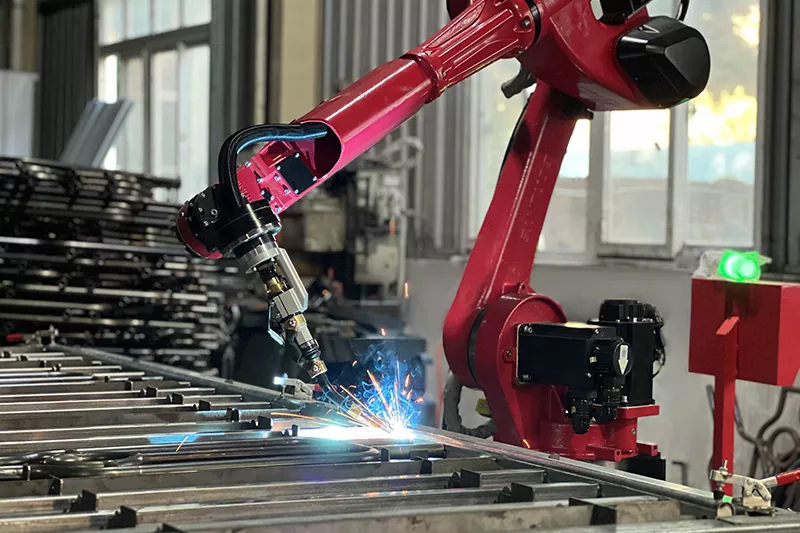

When embarking on industrial or construction projects, securing the right hardware isn't just a detail—it's a cornerstone of success. In the global supply chain, China stands out as a powerhouse for manufacturing quality components, including hanger bolts, which play a crucial role in ensuring stability and longevity. As you explore top hanger bolt manufacturers in China, it's essential to partner with reliable suppliers who prioritize precision and durability. At Topfence, we understand the importance of these connections, guiding you through the landscape of leading Chinese manufacturers to find solutions tailored to your specific needs. This blog post will dive into the key players in the industry, highlighting what sets them apart and how to choose the best fit for your projects. Join us as we uncover insights that can streamline your sourcing process and elevate your outcomes.

A Deep Dive into China's Premier Hanger Bolt Makers

China's hanger bolt industry has quietly become a global powerhouse, driven by a blend of traditional manufacturing expertise and cutting-edge innovation. Premier makers in regions like Zhejiang and Guangdong have honed their craft over decades, specializing in high-precision bolts used in furniture, construction, and automotive applications. By investing in advanced CNC machinery and rigorous quality control, these producers ensure durability and exact specifications, earning trust from international clients who rely on them for both standard and custom designs.

What sets these leading manufacturers apart is their ability to adapt swiftly to market trends and customer demands. For instance, many have embraced eco-friendly practices, using recyclable materials and energy-efficient processes to reduce their environmental footprint. They also leverage digital tools for seamless supply chain management, from raw material sourcing to final delivery, which enhances reliability and reduces lead times. This agility helps them stay ahead in a competitive global landscape, where consistency and flexibility are key.

Beyond technical prowess, China's premier hanger bolt makers emphasize strong customer relationships and innovative solutions. They often collaborate directly with clients to develop specialized products, such as corrosion-resistant bolts for harsh climates or lightweight options for modern architecture. This customer-centric approach, combined with continuous R&D, fosters long-term partnerships and drives industry growth, solidifying China's role as a go-to hub for quality fasteners worldwide.

Spotlight on Leading Suppliers for Your Hardware Needs

When it comes to sourcing hardware components, having access to top-tier suppliers can make or break your projects, from intricate electronic systems to robust industrial installations. These leading suppliers often stand out by delivering not just parts, but comprehensive solutions that include reliability, innovation, and scalability. For instance, companies like Digi-Key and Mouser Electronics have carved out niches by offering extensive inventories and rapid shipping, ensuring you can pivot quickly without downtime. Meanwhile, industry giants such as Arrow Electronics and Avnet provide deeper integrations with global supply chains, which is crucial for large-scale or specialized applications demanding consistent quality and support.

Beyond mere availability, the best suppliers distinguish themselves through value-added services that transform your procurement process. Look for partners who offer design assistance, detailed datasheets, and real-time inventory management tools—these features can streamline development cycles and reduce overhead. In sectors like automotive or aerospace, suppliers like TE Connectivity and Molex excel by adhering to stringent certifications and offering custom engineering support, ensuring components meet exacting standards. By focusing on these aspects, you can build resilient relationships that enhance product performance and mitigate risks in volatile markets.

Selecting the right supplier isn't just about ticking boxes; it's about finding a collaborator who aligns with your long-term goals and adapts to emerging trends such as IoT and sustainability. Some leaders are now prioritizing eco-friendly materials and energy-efficient designs, responding to growing consumer and regulatory demands. By spotlighting suppliers that innovate in these areas, you can future-proof your hardware investments and gain a competitive edge. Ultimately, a strategic approach to supplier partnerships fosters agility and drives success in a fast-paced industry.

How to Source Quality Hanger Bolts from Top Chinese Factories

Finding reliable hanger bolt suppliers in China starts with pinpointing factories that specialize in fasteners and have a proven track record in manufacturing these specific components. Look beyond general hardware producers to those that explicitly list hanger bolts in their product catalogs, as this often indicates deeper expertise in thread design and material selection. A practical tip is to use industry-specific platforms like Alibaba or Made-in-China, but don't just rely on ratings—dig into customer reviews and request samples to assess quality firsthand. Top factories typically offer clear certifications, such as ISO 9001, which can signal consistent production standards, but always verify these through third-party audits or direct communication.

Once you've shortlisted potential suppliers, focus on the specifics of hanger bolt quality, including materials like stainless steel or zinc-plated carbon steel, which affect durability and corrosion resistance. Engage in detailed discussions with factory representatives about tolerances, thread accuracy, and finish options to ensure they meet your exact requirements. Many buyers overlook the importance of packaging and logistics, so clarify these aspects early on to avoid damage during shipping. Visiting factories in person, if feasible, can provide invaluable insights into their production processes and quality control measures, helping you build a stronger partnership.

To differentiate your sourcing process, consider collaborating with factories that offer customization or rapid prototyping capabilities, allowing for adjustments based on your project needs. Staying updated on market trends, such as eco-friendly coatings or cost-effective alloy alternatives, can give you an edge in negotiations. Remember, a successful sourcing strategy involves not just finding a supplier but fostering a long-term relationship, so prioritize clear communication and regular quality checks to maintain consistency over time.

Innovations Shaping the Hanger Bolt Industry in China

China's hanger bolt industry is experiencing significant transformation driven by technological advancements and sustainability efforts. Manufacturers are increasingly adopting automated production lines and smart manufacturing systems that enhance precision and efficiency, reducing reliance on manual labor. This shift not only boosts output but also improves product consistency, meeting the rising demand from construction and industrial sectors while keeping costs competitive globally.

Innovations extend to materials science, with companies exploring eco-friendly alternatives such as recycled or high-strength alloys that offer durability with a reduced environmental footprint. Research is focusing on coatings and treatments that resist corrosion and wear, tailored to harsh environments like coastal or chemical plants. These material upgrades are giving Chinese hanger bolts an edge in international markets, where reliability and longevity are key selling points.

Beyond technology and materials, the industry is embracing digital tools like IoT and blockchain for supply chain transparency and quality traceability. This allows customers to verify product origins and specifications, building trust and enhancing brand reputation. Collaborations with universities and research institutes are fostering rapid prototyping and customization, enabling quick responses to niche market needs without sacrificing scalability.

Profiles of Trusted Manufacturers for Your Project Success

Choosing the right manufacturing partner can make or break your project, and our curated profiles of trusted manufacturers provide a clear picture of the expertise and reliability needed for your success. We delve into each manufacturer's track record, highlighting key projects and client testimonials that showcase their ability to deliver on time and within budget. By focusing on specific industries or technologies, these profiles help you match your unique requirements with a partner who truly understands the nuances of your field, ensuring a smoother collaboration from concept to completion.

Beyond just listing capabilities, we explore the human side of these manufacturers, sharing insights into their team dynamics, communication styles, and problem-solving approaches. For instance, you'll find details on how they handle unexpected challenges or adapt to changing market demands, which can be crucial for long-term project stability. This depth of information allows you to assess not only technical fit but also cultural alignment, fostering a partnership built on trust and mutual respect that goes beyond mere transactions.

In a crowded market, our profiles stand out by emphasizing transparency and real-world impact, such as case studies where manufacturers have driven innovation or achieved sustainability goals. We avoid generic descriptions, instead providing actionable insights like their response times, quality control processes, and post-delivery support. This approach helps you make informed decisions, reducing risks and maximizing the chances of your project's success by connecting you with partners who are genuinely invested in your vision and outcomes.

Navigating the Competitive Landscape of Hanger Bolt Suppliers

When sourcing hanger bolts, you're entering a market where a vast array of suppliers offer varying levels of quality, customization, and service. It's crucial to cut through the noise by identifying key differentiators. Beyond just catalog offerings, look for partners that specialize in niche applications or provide comprehensive engineering support, as these factors often separate standard vendors from industry leaders. Evaluating their track record on projects similar to yours can reveal much about their reliability and expertise.

The competitive landscape isn't just about price; factors like lead times, material availability, and compliance with international standards play pivotal roles. Some suppliers excel in rapid prototyping or offer eco-friendly alternatives, adding unique value that might align with your sustainability goals or tight deadlines. Engaging in direct conversations about their manufacturing processes and quality control measures can uncover hidden strengths that aren't always highlighted in marketing materials.

To stand out, consider suppliers that invest in ongoing innovation, such as developing corrosion-resistant coatings or optimizing bolt designs for specific industries like aerospace or furniture. Building long-term relationships with these forward-thinking companies often leads to better collaboration, custom solutions, and consistent quality over time, ensuring your projects remain competitive and efficient.

FAQ

Look for manufacturers with strong certifications like ISO 9001, good after-sales support, and a proven track record of delivering durable products for construction or furniture projects.

Request samples for stress testing and check if they comply with international standards such as ASTM or DIN, or visit their facilities if possible to inspect production processes.

Yes, many top manufacturers offer custom machining services, allowing you to specify dimensions, materials like stainless steel, and thread types to meet specific project needs.

Issues like long lead times or communication gaps can arise; mitigate these by working with suppliers that have English-speaking staff and clear contracts outlining delivery schedules.

They often use efficient mass production techniques and local material sourcing to reduce costs, while maintaining quality through strict in-house quality control checks.

Many manufacturers offer corrosion-resistant options, such as galvanized or zinc-plated bolts, ideal for outdoor structures or marine applications.

Expect services like logistics assistance, technical consultations, and warranty coverage to help streamline procurement and project implementation.

Conclusion

China stands as a global hub for hanger bolt manufacturing, offering a wealth of premier makers and leading suppliers that cater to diverse hardware needs. A deep dive into the market reveals a competitive landscape where top factories, often highlighted in supplier spotlights, combine advanced production capabilities with stringent quality control to ensure reliable sourcing for your projects. These trusted manufacturers leverage extensive experience and specialized expertise to deliver hanger bolts that meet international standards, making it easier to navigate the complexities of global supply chains and secure components that drive project success.

Beyond mere production, innovation is shaping the hanger bolt industry in China, with manufacturers integrating new materials and precision engineering techniques to enhance durability and performance. By profiling these innovators, businesses can discover how to source quality hanger bolts efficiently, tapping into factories that prioritize customization and scalability. This dynamic environment emphasizes strategic partnerships, where understanding manufacturers' profiles and industry trends allows for smarter procurement decisions, ultimately ensuring that your projects benefit from cutting-edge solutions and competitive advantages in a fast-evolving market.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/