How do Stringing Blocks help in reducing cable friction?

2024-11-12

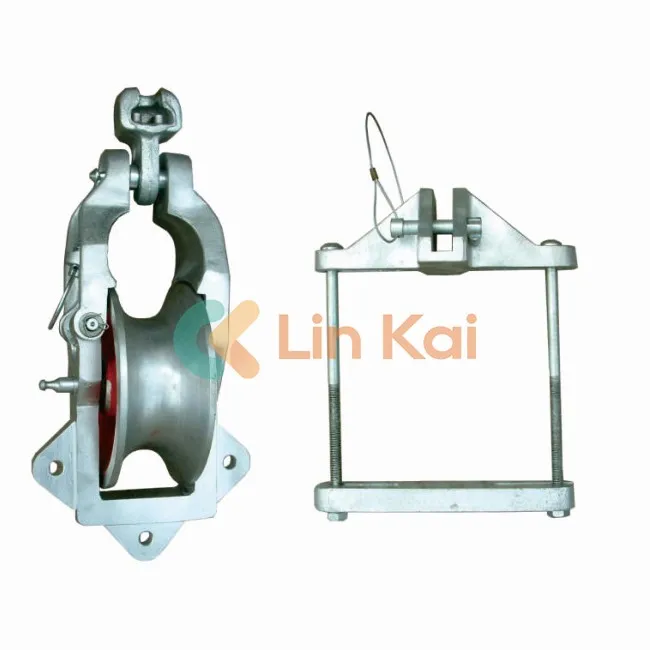

Stringing blocks are crucial tools in power line and telecommunication cable installations, helping to reduce cable friction as cables are pulled over long distances and around various obstacles. These blocks, often placed on poles or structures along the installation path, provide a smooth, guided path for the cable, preventing it from directly contacting rough surfaces that could create resistance and potential damage. Here’s how they work to minimize friction:

1. Smooth and Rolling Surfaces

Stringing blocks are designed with smooth, often roller-based surfaces (such as pulleys or wheels) that the cable can glide over. The rolling motion provided by the block minimizes the frictional force that would otherwise occur if the cable were dragged along a static surface. This helps prevent the cable from wearing down or getting damaged by rough edges or obstructions.

2. Guiding the Cable Along the Optimal Path

Stringing blocks are positioned along poles or towers to keep the cable on an optimal, pre-determined path. This prevents the cable from making direct contact with poles, branches, or other obstacles, which would otherwise create significant friction. Instead, the cable is guided around corners and along turns, reducing the resistance encountered along the way.

3. Reducing Bending Stress at Angles and Corners

In installations where cables need to be routed around corners or angled poles, stringing blocks support the cable as it bends. Without a block, these angles would cause increased tension and friction as the cable rubs against stationary objects. The rolling motion of stringing blocks reduces the frictional force needed to pull the cable around these curves, lessening wear and the likelihood of cable stretching or damage.

4. Even Load Distribution

Stringing blocks distribute the weight and pulling force of the cable evenly across multiple blocks. This prevents excessive tension or drag at any one point, allowing the cable to move more freely without unnecessary friction. When spaced at regular intervals, stringing blocks ensure a consistent path with low resistance.

5. Specialized Coatings and Materials

Many stringing blocks are designed with coatings or materials, like nylon or polyurethane, that reduce friction between the cable and the block’s surface. These materials minimize wear on both the cable and the block, especially helpful when dealing with heavy or high-voltage cables that would otherwise experience high friction and wear.

Summary

Stringing blocks are indispensable for reducing cable friction during installation, ensuring a smooth, controlled path that prevents direct contact with rough or stationary surfaces. By minimizing tension, wear, and stress, these blocks extend the cable’s lifespan and make installation safer and more efficient. Their design and strategic placement help reduce both friction and potential cable damage, making them essential in overhead line construction and maintenance.