What Are the Differences Between Polyacrylamide and Polyacrylic Acid in Industrial Applications?

2025-10-31

In modern industries, high-performance polymers such as Polyacrylamide (PAM) and Polyacrylic Acid (PAA) play crucial roles in processes ranging from water treatment to oil recovery. At Nuoer Energy, our focus has always been on delivering superior Oilfield Chemical solutions that meet specific customer needs. Understanding the differences between these two polymers helps industrial users choose the right material for their operations. This article provides an in-depth comparison based on structure, performance, and applications.

Chemical Structure and Composition

Polyacrylamide and Polyacrylic Acid share a similar carbon backbone but differ in their functional groups, which directly affect their solubility, reactivity, and field performance. Polyacrylamide contains amide groups that make it suitable for flocculation and thickening, while Polyacrylic Acid features carboxylic acid groups that enhance ion exchange and dispersing capabilities. In our factory, both polymers are produced under strict quality control standards to ensure stability in diverse industrial environments.

| Property | Polyacrylamide (PAM) | Polyacrylic Acid (PAA) |

| Chemical Formula | (C3H5NO)n | (C3H4O2)n |

| Functional Group | Amide (-CONH2) | Carboxyl (-COOH) |

| Ionic Type | Nonionic, Anionic, or Cationic | Primarily Anionic |

| Solubility | Completely soluble in water | Highly soluble in water |

| Main Application Fields | Oilfield Chemical, wastewater treatment, papermaking | Dispersants, scale inhibitors, detergents |

| pH Range Stability | 5.0 – 9.0 | 4.0 – 10.0 |

| Thermal Stability | Moderate (up to 80°C) | High (up to 120°C) |

Performance Comparison in Industrial Applications

Our team at Nuoer Energy understands that performance under real industrial conditions is what truly defines product value. Polyacrylamide excels in applications requiring particle aggregation and viscosity control, making it a key Oilfield Chemical for enhanced oil recovery and sludge dewatering. In contrast, Polyacrylic Acid is favored for its superior dispersing ability, especially in cleaning formulations and water treatment processes.

In oilfield operations, Polyacrylamide improves fluid mobility and reduces water channeling, thereby increasing crude oil extraction efficiency. Meanwhile, Polyacrylic Acid effectively prevents scale formation and maintains system cleanliness. Our products are customized to meet each client’s process needs, ensuring cost-effectiveness and high operational reliability.

Environmental and Safety Considerations

As part of our corporate commitment to sustainability, Nuoer Energy ensures that all Oilfield Chemical formulations comply with international environmental standards. Polyacrylamide is typically used in low concentrations and has minimal ecological impact when properly handled. Polyacrylic Acid, due to its biodegradable properties, is suitable for environmentally conscious industries such as textiles and detergents. Our factory uses advanced purification processes to reduce residual monomer content, ensuring product safety for both users and the environment.

Key Advantages of Nuoer Energy’s Oilfield Chemicals

Our factory has been producing and exporting Oilfield Chemical products for over a decade. We emphasize molecular weight control, polymer chain uniformity, and high purity levels. Our Polyacrylamide and Polyacrylic Acid grades are widely applied in oil extraction, drilling fluids, wastewater management, and industrial process optimization. With consistent R&D investments, Nuoer Energy has developed customized copolymer blends that outperform standard market formulations in demanding conditions.

Technical Specifications from Our Factory

| Product Name | Polyacrylamide (PAM) | Polyacrylic Acid (PAA) |

| Molecular Weight Range | 5 – 20 million | 1 – 5 million |

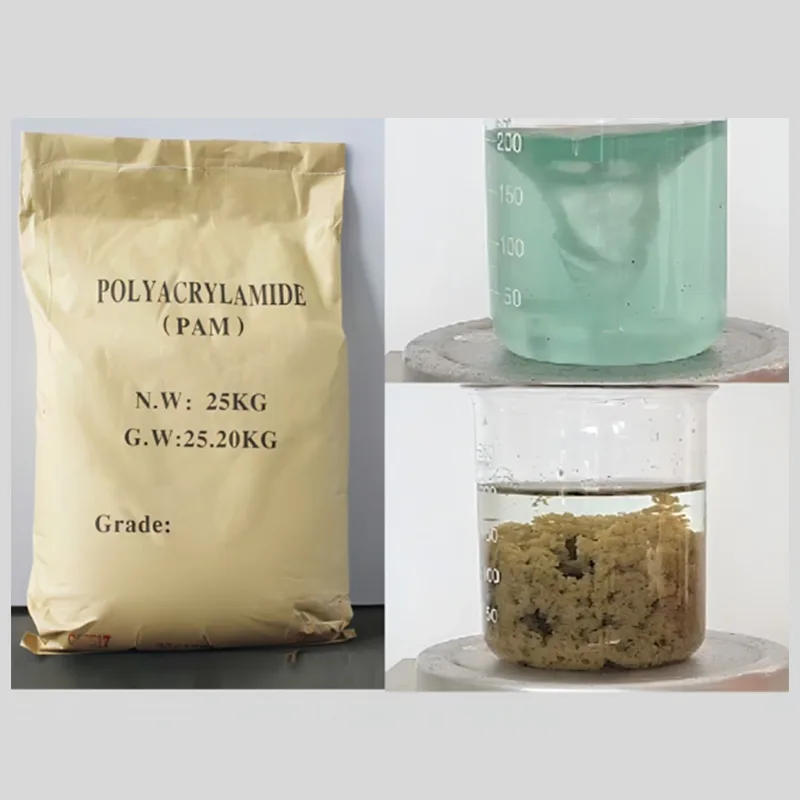

| Appearance | White granular or powder form | White to light yellow powder |

| Solid Content | ≥ 88% | ≥ 90% |

| Residual Monomer (ppm) | < 500 | < 300 |

| Application Dosage | 0.1–1.0 g/L | 0.5–2.0 g/L |

| Packaging | 25 kg kraft bags or customized drums | 25 kg kraft bags or customized drums |

Practical Application Scenarios

At Nuoer Energy, our engineers frequently assist customers in selecting between Polyacrylamide and Polyacrylic Acid based on site-specific factors. For instance, in oilfield polymer flooding, our Polyacrylamide series enhances viscosity control and improves sweep efficiency. Meanwhile, for desalination plants or industrial boilers, our Polyacrylic Acid formulations effectively inhibit scale and corrosion, reducing maintenance downtime. These application differences demonstrate why having both polymers in our product portfolio gives our clients flexibility and technical advantage.

FAQs About “What Are the Differences Between Polyacrylamide and Polyacrylic Acid in Industrial Applications?”

Q1: Why are Polyacrylamide and Polyacrylic Acid used in similar industries?

A1: Both polymers share water solubility and functional versatility. However, Polyacrylamide provides better flocculation and thickening effects, while Polyacrylic Acid acts as an excellent dispersant and scale inhibitor. Nuoer Energy offers both types to suit different industrial purposes.

Q2: How do I decide which polymer is suitable for my process?

A2: Selection depends on operating conditions such as pH, temperature, and chemical environment. Our factory’s technical team evaluates these parameters and recommends the most cost-effective polymer solution for consistent results.

Q3: Are these polymers environmentally safe?

A3: Yes, when used according to proper guidelines. Our Oilfield Chemical products from Nuoer Energy meet international environmental standards and are designed to minimize residual monomers, ensuring low toxicity and high biodegradability.

Conclusion

In conclusion, while Polyacrylamide and Polyacrylic Acid may appear similar at first glance, their differences in molecular structure and application behavior make each uniquely valuable across various industrial sectors. At Nuoer Energy, we take pride in producing high-quality Oilfield Chemical products through advanced technology and precision engineering. By partnering with our factory, customers gain access to reliable, customizable solutions that enhance efficiency, safety, and sustainability in their operations.